With version 1.18.0, users can take advantage of several new features for Impositions, automated processing of Print Data, and Approval Projects. In addition, improvements have been made to Data Preparation, Color Management, Print Data management, and further translations.

Features

- In the user interface of the Impose Editor, improvements have been implemented concerning the labeling of the individual function areas. Furthermore, the font for all affected tabs has been standardized

- The functionality of the available strategies has been improved and the logic for the Nesting mode has been revised. The logic has also been improved for single- and multi-page Impositions.

- A new option has been created to alternate and recur multiple Print Items in rows in Step & Repeat.

- The functionality of minimum overproduction and underproduction, which were implemented in version 1.17.0, has been optimized in terms of calculation and the user interface has been slightly adapted.

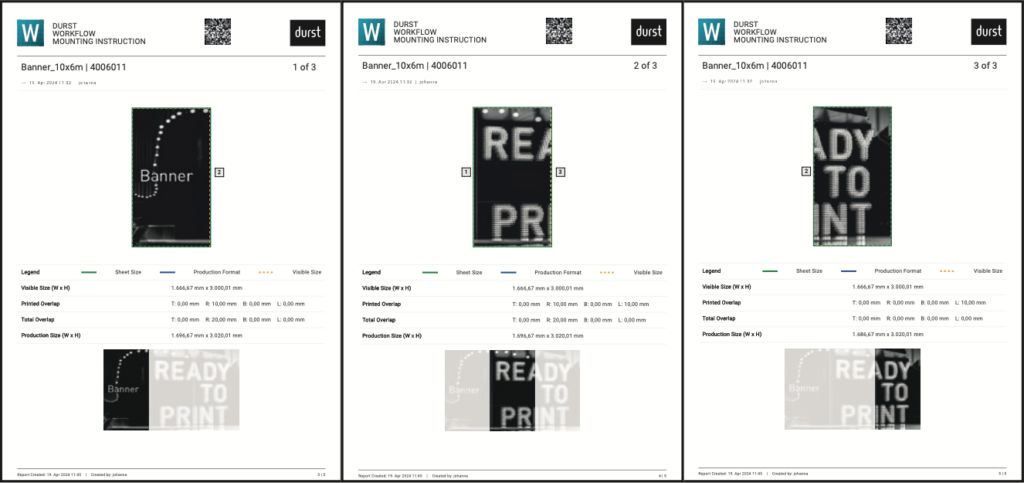

- In Tiling mode, it is possible to set the starting point for numbering the Tiles and to create Mounting Instructions without rendering the Tiling first.

- As of this version, the caption is cut to the width of the print object – ImageBox or ImageBox + Bleed – to avoid overlaps in neighboring print objects with long captions.

- Multiline Captions – It is now possible to create multi-line captions for a Print Item.

- From version 1.18.0, it is possible to create Dielines around Captions. It is also possible to merge the Dieline of the Caption with the actual Dieline of the Print Item, so that a kind of tab is created for the Caption on the Print Item.

Automation

Since version 1.17.2, it has been possible for beta customers to use Automation Jobs in conjunction with the new Workflow user interface. This function provides users with the option of defining and scheduling completely automated production processes according to their requirements. From this version onwards, further functions will be available to further advance the possibilities of automation.

Approval Reports

The new structure introduced with version 1.17.2 – working with Approval Projects – in the Create Approval Reports environment has been further expanded in version 1.18.0.

While minor improvements have been made to the creation of Approval Projects and the Dashboard for Approval Projects, the online Approval Dashboard has been completely restructured and access has been simplified.

PDF Printer

Improvements

Grid Charts

The standardization of all Grid Charts in terms of output and functionality has been completed.

Check-In Check and Fixup Templates

Die Cut Management

Inks

Die Cut Management

One-Up

N-Up

Sheet ID

Waste number in N-Up

In order to better control further processing, areas to be broken out can be provided with a so- called waste number.

One-Up Number in a One-Up

A One-Up Number can be added to stored One- Ups. This number is filled in automatically if this One-Up is linked to a N-Up. In the Die Cut mode of the Impose Editor, the user is shown how many One-Ups are placed on the sheet.

Please see our release notes for details.