Version 1.20.0 offers users a number of new features in the Impose Editor, the new User Interface, Process Automation and Data Preparation.

Features

Update Information

You cannot update directly from an earlier version, such as 1.18.x, 1.17.x, or 1.16.x, without first updating to version 1.19.0.

Captions in the Impose Editor

The following new features are available for captions:

- New Placeholders for Production Jobs – the available placeholders have been expanded to include the “Render date” and “Render time”.

- New placeholder for each Print Item and Imposition – sequential numbering for each Print Item and Imposition can now be added.

- Perforation for flaps – a perforated line can be created and transferred to the Cutter Device.

Nesting – a new strategy

“Keep Print Items on page together” is now also correctly visualized for multipage nesting.

Nesting – remove unplaced Print Items

When saving an Imposition, a dialog appears in which the user can choose whether the unplaced Print Items should be removed from the Production Job or retained.

Step&Repeat

The following new features are available in the Mode Step&Repeat:

- Pre-Angulation – this feature has been implemented for this Impose mode as well with version 1.20.0.

- Captions “Per Row” – allows you to add captions for each row of motifs in Step&Repeat.

- Marks and captions for “Last row” – this allows you to add a mark or caption for the last motif row in a multipage Imposition.

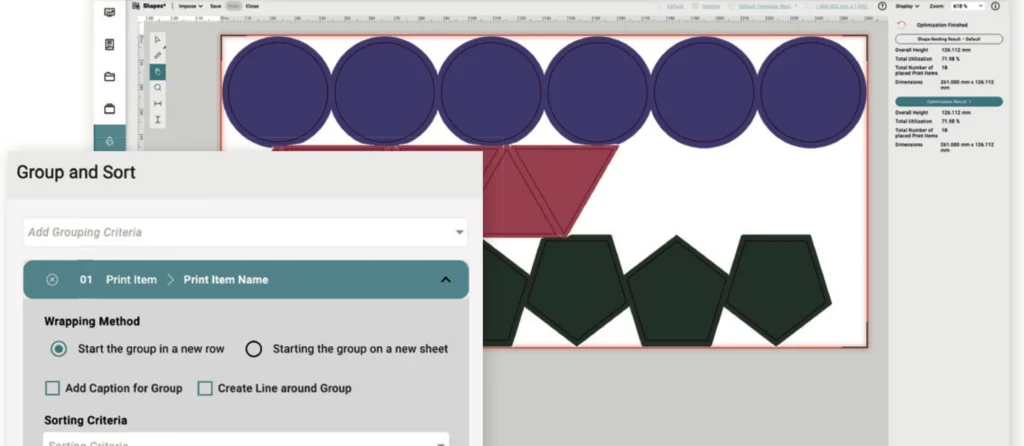

Shape Nesting

The following new features are available in the Mode Nesting:

Available rotations – there are several rotation options for nesting optimization:

- 4 rotations – 90°

- 8 rotations – 45°

- 16 rotations – 22.5°

- Any number of rotations – user-defined

Group and Sort – Shape Nesting uses the same grouping and sorting logic that is already available in Nesting mode.

Placing Registration Marks – The “Best Fit” mode has been improved so that more marks are now placed along the stroke.

Automation – Production Scheduler

Users can refer to new features in the Production Scheduler environment, including newly added and improved filter options and a redesigned interface for sorting the list of Production Schedulers.

New Routine-Settings

The new user interface provides users with improved filter options and a redesigned interface. From now on, only four routines will be delivered.

Offcut Optimization

Provides the function to place print items vertically or horizontally in a Nesting to create the largest possible offcut. If the offcuts are the same size vertically and horizontally, the offcut with the smaller width-to-height ratio is preferred. This allows the offcut to be reused in production.

Dynamic naming

The user can use a system setting to dynamically generate the name and external ID of a Production Job. Numerous placeholders can be used for this purpose. This naming convention applies to both classically generated Production Jobs and those created via Hotfolders or automations.

Approval Projects

This version provides the ability to synchronize selected content from the workflow with the Approval Portal. It also provides the ability to send new data to the workflow via the Approval Portal, allowing customers to quickly submit new data.

New logic for deletion

Selected Orders or Production Jobs and the associated Print Items can be moved to the trash or deleted directly.

New Data Preparation

Set Line Width for Selected Spot Colors – The line width of spot color objects (e.g., technical spot colors) can be changed to a defined value

New user interface

With this version, the user can access many functions in the new user interface, including the following:

- Creating and editing Routines

- Information – hardware resources, interfaces, installed version, license

- Creating and editing Hotfolders

- Printer list

- Print Item detail view

- Multipage Print Items

- Preflight results per page

Improvements

Amazon Transparency Codes

Starting with this version, access information for the Amazon Transparency Server can be assigned to a customer and saved. This means that users do not need to save the access data elsewhere.

Special technical Colors – mandatory labeling

Starting with this version, special technical Colors must be identified with a Processing Steps Group and a Processing Steps Type by the ISO Standard 19593-1 – Processing Steps.

Please see our release notes for details.